Valve repair machines on flat and conical surfaces

Serco is located in the heart of the petrochemical and nuclear plants of the industrial valley of the Rhone Alps in France.

Serco began its activities in 1984 to provide solutions in the areas of valve and flange facing for field work.

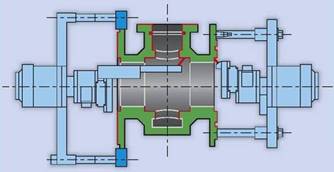

SERCO machines are positioned and fixed by a column clamping system fixed on the outside, thus allowing internal machining of the part. The clamping is very fast and in minutes parallelism and concentricity of 1/100 mm can be obtained. The motors are pneumatic and hydraulic may be required.

Serco UR

Unit for machining valve seats. Can be used with SERCO TU and TA machines

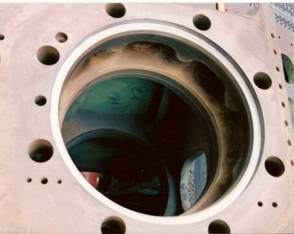

Boring Machine SERCO TA 240/220/ME/SP

Can be used in PC2 Pielstick diesel engines. In the photo we see the boring operation in the lower part and facing of the upper part (entablature).

Faceo operation in “lining” of a Sulzer ZA 40 diesel engine with the SERCO TU 600

Sulzer ZA 40 diesel engine just after being machined

Facing operation on a Boss reactor with the SERCO TU 1100

Parts that can be machined

|